Our Experience

You can measure a company by its experience and Energyficient has a lot of it. We have an extensive and diverse history of projects that showcase our abilities.

- Continuing Education

- Parking Lots

- Warehouses

- Repair Facilities

- Food Processing

- Commercial Retail

- K-12 Education

- Industrial Manufacturing

- Special Projects

Indian Hills Community College

Ottumwa, Iowa

Annual Cost Savings: $28,814.50

Square Footage: 256,386 ft2

Annual kWH Savings: 391,501 kWH

Annual kW Savings: 108 kW

Project Summary:

Indian Hills Community College is a community minded institute of higher learning. Their mission is not only to provide students with a strong education, but also to meet the developing needs of the business community in the surrounding small towns and rural areas. The roots of IHCC’s rich history in southern Iowa can be traced all the way back to the 1860’s with the establishment of the Visitation Academy on what is now the Ottumwa Campus. IHCC’s need to constantly evolve to meet the needs of the community has led to many renovations and newly constructed facilities.

Priorities for this project were electrical savings, user comfort, maintenance savings, and parts consolidation. When it was time to bring their systems up-to-date, they turned to the team of professionals at Energyficient.

This project included two buildings: the Net Center and the Student Life Center. In the Net Center, the HID lighting in the court area was replaced with a new direct fluorescent system to get to NCAA recommended light levels of 80fc and uniformity requirements. Controls were added to the court lighting for high/low operation and occupancy based control. All existing wiring to lighting was also replaced.

In the Student Life Center the existing HID lighting in the basketball court/track area was replaced with a new direct fluorescent system. Controls were added to the court lighting for high/low operation and occupancy based control. Racquetball courts were retrofitted with induction lighting kits, with 100,000 hour lamp life. The existing can lights were also retrofitted with new LED retrofits.

Project Benefits:

- Reduction in Replacement Parts

- Lifelong Energy Savings

- Maintenance Cost Savings

- Improved Safety

- Bi-Level lighting provides significant energy savings by working on the premise the light level should match the activity. Recreational activities like tennis and volleyball do not require as much light as NCAA does for play.

- Occupancy sensors over the courts effectively keep the lights off of the courts when not needed. Each court was equipped with sensors that detect when the court is vacant and turn off lights when not needed, providing significant energy cost savings.

Project Information

| Square Footage | 256,386 ft2 |

| Return on Investment | 13% |

| Payback | 26.62 months |

| Electric Cost Savings (Annually) | $28,814.50 |

| Incentives Achieved | $35,235.12 |

| Total Watts Saved | 96,377 Watts |

| kWH Annual Savings | 391,501 kWH |

| kW's Removed | 107,000 |

| Lamp Types Removed from Inventory | 1 |

| Affected Fixtures | 389 |

| Occupancy Sensors | 45 |

| New Fixtures Installed | 13 |

| Ballasts Installed | 136 |

| Reflector Kits Installed | 87 |

| CFL's Installed | 0 |

| T8 Lamps Installed | 1,607 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | lbs |

| Nitrogen Oxide (NOx) | XX lbs |

| Acid Rain (Sulfur Dioxide, SO2) | XX lbs |

| Mercury (Hg) | XX lbs |

| Carbon Monoxide (CO) | XX lbs |

Natural Resources Savings

| Coal | XX lbs |

| Oil | XX gal |

| Natural Gas | XX gal |

Mundelein Metra Station

Village of Mundelein, IL

Annual Cost Savings: $15,225.70

Annual kWH Savings: 199,813 kWH

Annual kW Savings: 45.41 kW

Project Summary:

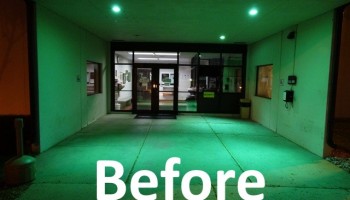

The design engineers at Energyficient achieved extraordinary energy cost savings and a dramatic lighting

improvement for the village by choosing new LED lights with very specific light distributions.

As shown here, the uniformity of light is remarkably improved which increases visibility and reduces wasted energy by removing those hot spots found under the original lights.

Project Benefits:

- Extraordinary cost and energy Savings

- Wasted energy reduced with the removal of hot spots

- Safe, well-lit environment for patrons, no dark spots.

- Light uniformity created

Project Information

| Electric Cost Savings (Annually) | $9,050.04 |

| Maintenance Savings (Annually) | $6,175.66 |

| Incentives Achieved | DCEO Rebate $9,375 |

| Total Watts Saved | 45,410 |

| kWH Annual Savings | 29,598 kWH |

| kW's Removed | 45.41 |

| Affected Fixtures | 52 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 452,376.18 lbs |

| Nitrogen Oxide (NOx) | 1,103.17 |

| Acid Rain (Sulfur Dioxide, SO2) | 2,016.11 lbs |

| Mercury (Hg) | 7,133.32 lbs |

| Carbon Monoxide (CO) | 65.74 lbs |

Natural Resources Savings

| Coal | 97,908.27 lbs |

| Oil | 593.44 gal |

| Natural Gas | 3,316.24 gal |

Refreshment Services Pepsi

Burlington , IA

Annual Cost Savings: $13,090.09

Square Footage: 39,000 ft2

Annual kWH Savings: 126,823 kWH

Annual kW Savings: 27,300 kW

Project Summary:

The existing lighting system was originally designed, at least partially, for a bottling operation. The spacing and layout of the current system is not ideal for a one fixture replacement in all areas. The existing system is likely over 20 years old and at the peak of its maintenance needs. The old system primarily uses T12 glass fluorescent tubes, and is  providing only about half the light level normally specified for a warehouse environment.

providing only about half the light level normally specified for a warehouse environment.

Our new system design replaces the existing system with a fresh layout designed especially for the needs of the modern day warehouse. It will provide the proper light levels for a safe and productive work environment, eliminate glass, and reduce electricity and maintenance costs substantially.

Human Return on Investment:

Improvement of light quality, uniformity and glare control for safe and productive work environment. All while substantially reducing glass as well as the cost of energy and maintenance.

work environment. All while substantially reducing glass as well as the cost of energy and maintenance.

Update and improve the look and feel of office lighting to adequate light levels for performance with new volumetric LED type troffer.

Project Benefits:

Project Information

| Square Footage | 39,000 ft2 |

| Return on Investment | 24% |

| Payback | 43.2 months |

| Electric Cost Savings (Annually) | $11,287.29 |

| Incentives Achieved | EPACT $8,936.49 |

| Total Watts Saved | 27,300 Watts |

| kWH Annual Savings | 126,823 kWH |

| kW's Removed | 27.30 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 291,693.89 lbs |

| Nitrogen Oxide (NOx) | 597.85 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 1,022.07 lbs |

| Mercury (Hg) | 3,462.28 mg |

| Carbon Monoxide (CO) | 47.05 lbs |

Natural Resources Savings

| Coal | 62,143.48 lbs |

| Oil | 376.67 gal |

| Natural Gas | 2,104.85 gal |

Deery Collision Center

Burlington , IA

Annual Cost Savings: 23,645.36

Annual kWH Savings: 200,735 kWH

Annual kW Savings: 66.42 kW

Project Summary:

“The facility is better and brighter!”

The Deery Collision center body shop upgrade was much needed due to an inefficient lighting system. Now that the project is complete, employees say the work facility is better and brighter, and a great working environment for auto repair.

Project Benefits:

- Sustainable Electricity Savings

- Maintenance Cost Savings

- Maintenance Parts Consolidation

- Inventory Reduction

- Technology Standardization

- Warranty Standardization

- Improve Light Quality

- Uniformity and Glare Control

Project Information

| Return on Investment | 24% |

| Payback | 40.9 |

| Electric Cost Savings (Annually) | $20,675.68 |

| Incentives Achieved | KCPL Rebate $18,252.92 |

| kWH Annual Savings | 200,735 kWH |

| kW's Removed | 66.42 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 273,064.28 lbs |

| Nitrogen Oxide (NOx) | 559.66 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 956.79 lbs |

| Mercury (Hg) | 3,241.15 lbs |

| Carbon Monoxide (CO) | 44.05 lbs |

Natural Resources Savings

| Coal | 58,174.56 lbs |

| Oil | 352.61 gal |

| Natural Gas | 1,970.42 gal |

Pinnacle Foods, Inc

Centralia, IL

Annual Cost Savings: $76,718.53

Square Footage: 185,304 ft2

Annual kWH Savings: 1,578,926 kWH

Annual kW Savings: 126.81 kW

Project Summary:

Pinnacle Foods, Inc. is a packaged foods company specializing in shelf-stable and frozen foods. In food processing applications, lighting systems must be able to endure the tough conditions and demanding environments, which is why the right lighting is critical. Using a combination of new LED fixtures and retrofits, our design team engineered, implemented, and constructed a energy saving solution for a facility wide LED upgrade – providing substantial energy savings year after year.

Pinnacle Foods, Inc. is a packaged foods company specializing in shelf-stable and frozen foods. In food processing applications, lighting systems must be able to endure the tough conditions and demanding environments, which is why the right lighting is critical. Using a combination of new LED fixtures and retrofits, our design team engineered, implemented, and constructed a energy saving solution for a facility wide LED upgrade – providing substantial energy savings year after year.

Pursuing energy savings at an affordable cost, led us to utilize cutting-edge technology throughout the facility. Metal halide, class 2, div 2 pendant mount fixtures were replaced with high-performance hazardous location (class 2, div 2) high bay fixtures to evenly illuminate work areas. New fixtures not only provide savings on the electric bill, but reduce maintenance needs through a more reliable lighting solution. And in the demanding industrial spaces, having proper illumination is essential for safety.

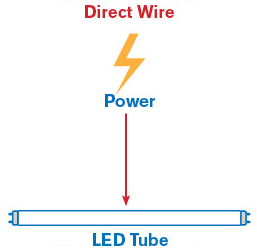

Linear fluorescent fixtures were retrofitted with ballast bypass LED tubes, which offer the lowest cost of ownership. Removing the fluorescent ballast and operating tubes directly off main voltage is more reliable and offers greater energy savings compared to other retrofit options. To optimize energy savings and extend fixture life, occupancy sensors were installed in office spaces. Using sensors helps maintain the workplace by automatically turning the lights on/off based off of the rooms vacancy.

On the outside, wall pack and flood light fixtures were replaced with LED fixtures while industrial jar fixtures were retrofitted with LED lamps. A majority of exterior fixtures ran 24/7 due to faulty photocell control. Installed fixtures had an on-board photocell to correct that issue and provide Pinnacle Foods with greater energy savings.

Implementing an extensive list of LED lighting and control products will help contribute to a clean, safe, and visually effective work environment. Minimizing costs associated with operation and maintenance in a cost-effective way is something Pinnacle Foods will benefit from year after year.

Project Benefits:

- Bright, crisp light with balanced distribution for a safer, comfortable work environment

- Instant on - no warm up/turn on time

- Durable, food safe fixtures with longer life (average 75,000+ hrs)

- Reduced inventory by consolidated fixture and lamp types

- Optimized energy savings with occupancy sensors and exterior photocell control

Project Information

| Square Footage | 185,304 ft2 |

| Return on Investment | 34% |

| Payback | < 3 years |

| Electric Cost Savings (Annually) | $76,718.53 |

| Maintenance Savings (Annually) | $14,934.43 |

| Incentives Achieved | Ameren Illinois Rebate ≈$60k |

| Total Watts Saved | 185,481 Watts |

| kWH Annual Savings | 1,578,926 kWH |

| Affected Fixtures | 1,197 |

| Removed Fixtures | 14 |

| New Fixtures Installed | 762 |

| Fixture Retrofits | 421 |

| Installed Occ Sensors | 23 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 3,574,688.29 lbs |

| Nitrogen Oxide (NOx) | 8,717.25 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 15,931.36 lbs |

| Mercury (Hg) | 56,367.66 mg |

| Carbon Monoxide (CO) | 519.47 lbs |

Natural Resources Savings

| Coal | 773,673.70 lbs |

| Oil | 4,689.41 gal |

| Natural Gas | 26,205.00 gal |

Snyder’s-Lance Private Brands

Burlington, IA

Annual Cost Savings: $133,000

Square Footage: 525,000 ft2

Annual kWH Savings: 2,161,777 kWH

Annual kW Savings: 206 kW

Town Center of Aurora

Aurora, Colorado

Annual Cost Savings: 29,130.00

Annual kWH Savings: 192,202 kWH

Annual kW Savings: 52.66 kW

Project Summary:

The Town Center in Aurora, Colorado is an enclosed, two-level shopping center that is home to over 130 stores and restaurants. With aging equipment, it was becoming increasingly expensive to operate and maintain the nearly 900 recessed downlight fixtures that existed throughout the center’s interior.

After meeting with key facility managers to determine the project’s needs and goals, we engineered and implemented an LED design solution that was cost-effective, energy efficient, and dependable. Using an eight-inch LED recessed downlight retrofit kit allowed us to deliver high performance white light while optimizing annual savings. And by reusing existing eight-inch frames, installation was done quickly and easily.

The benefits of an LED retrofit project are significant for the Town Center of Aurora. By using a low wattage solution, we reduced the amount of energy used for lighting by nearly 70%, which helped establish a quick payback period. Maintenance and associated costs have also been minimized with the fixture’s longer rated life of over 120,000 hours. Performance optics efficiently direct light in a balanced output with low glare, creating a comfortable environment for all shoppers.

Project Benefits:

- Sustainable annual electric and maintenance savings

- Balanced, low glare light output

- Consolidated lamp types, reduced inventory

- Increased fixture life (120,000+ Hours)

- Cost-effective with quick payback

Project Information

| Return on Investment | 25% |

| Payback | <4.5 years |

| Electric Cost Savings (Annually) | $17,000 |

| Incentives Achieved | Xcel Energy Rebate ≈$42K |

| Total Watts Saved | 52,658 Watts |

| kWH Annual Savings | 192,202 kWH |

| kW's Saved | 52.66 kW |

| Lamp Types Removed from Inventory | 214 Compact Fluorescent Lamps

758 Metal Halide Lamps |

| Affected Fixtures | 865 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 400,740.54 lbs |

| Nitrogen Oxide (NOx) | 695.39 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 811.28 lbs |

| Mercury (Hg) | 1,080.17 mg |

| Carbon Monoxide (CO) | 79.19 lbs |

Natural Resources Savings

| Coal | 94,178.83 lbs |

| Oil | 570.84 gal |

| Natural Gas | 3,189.92 gal |

Project Summary:

For a car dealership, lighting is critical for attracting customers to the lot and getting them in a vehicle they can drive home. JD Byrider understood this importance and asked the team at Energyficient to engineer a LED solution that would dramatically transform the nighttime appearance of four of their Iowa dealership locations.

For a car dealership, lighting is critical for attracting customers to the lot and getting them in a vehicle they can drive home. JD Byrider understood this importance and asked the team at Energyficient to engineer a LED solution that would dramatically transform the nighttime appearance of four of their Iowa dealership locations.

The front row at each location is a critical selling area that required strategic thought during the design phase. Energyficient engineers had to identify a way to increase the visual impact of the front row while providing sustainable annual savings with controlled light trespass. Using Hubbell-Beacon’s Viper series fixtures we provided outstanding performance at an exceptional value. Delivering industry leading performance, this fixture maximized efficiency with bright, uniform distribution and minimal light trespass.

While new fixture replacements significantly increased energy and maintenance savings, untapped savings still remained without proper controls. Fixtures were integrated with Hubbell’s SiteSync lighting control. SiteSync is a simple, reliable, and affordable wireless control that immediately reduces power consumption and minimizes maintenance costs while delivering the right amount of light. With simple and easy field commissioning, we programmed fixtures to dim down during off-hours to optimize annual savings.

Project Benefits:

- Improved visual impact of front rows & building facades.

- Reduced dark spots with bright, uniform distribution

- Enhanced overall safety & security

- Autonomous wireless control for increased cost savings

- Minimized light trespass to surrounding roads and businesses

- Sustainable energy savings through long lasting, low maintenance, energy efficient fixtures

Project Information

Burlington, IA Location

| Return on Investment | 40% |

| Payback | <2.5 years |

| Electric Cost Savings (Annually) | $5,500 |

| Incentives Achieved | Alliant Energy Rebate ≈$6,500 |

| Total Watts Saved | 9,101 Watts |

| kWH Annual Savings | 40,830 kWH |

| Affected Fixtures | 21 |

| New Fixtures Installed | 13 |

| Retrofits Installed | 0 |

| Removed Fixtures | 8 |

Cedar Rapids, IA Location

| Return on Investment | 50% |

| Payback | <2 years |

| Electric Cost Savings (Annually) | $9,300 |

| Incentives Achieved | Alliant Energy Rebate ≈$18,500 |

| Total Watts Saved | 28,262 Watts |

| kWH Annual Savings | 123,800 kWH |

| Affected Fixtures | 40 |

| New Fixtures Installed | 30 |

| Retrofits Installed | 0 |

| Removed Fixtures | 10 |

Davenport, IA Location

| Return on Investment | 35% |

| Payback | <3 years |

| Electric Cost Savings (Annually) | $6,500 |

| Incentives Achieved | MidAmerican Energy Rebate ≈$20,000 |

| Total Watts Saved | 32,977 Watts |

| kWH Annual Savings | 147,660 kWH |

| Affected Fixtures | 46 |

| New Fixtures Installed | 31 |

| Retrofits Installed | 0 |

| Removed Fixtures | 15 |

Des Moines, IA Location

| Return on Investment | 35% |

| Payback | <3 years |

| Electric Cost Savings (Annually) | $7,090 |

| Incentives Achieved | MidAmerican Energy Rebate ≈$25,000 |

| Total Watts Saved | 36,786 Watts |

| kWH Annual Savings | 159,910 kWH |

| Affected Fixtures | 57 |

| New Fixtures Installed | 31 |

| Retrofits Installed | 12 |

| Removed Fixtures | 14 |

Pollution Reduction

All Locations Combined

| Global Warming (Carbon Dioxide, CO2) | 1,086,017.55 lbs |

| Nitrogen Oxide (NOx) | 2,225.85 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 3,805.31 lbs |

| Mercury (Hg) | 12,890.56 lbs |

| Carbon Monoxide (CO) | 175.19 lbs |

Natural Resources Savings

All Locations Combined

| Coal | 231,368.95 lbs |

| Oil | 1,402.38 gal |

| Natural Gas | 7,836.67 gal |

Project Summary:

The priority of the lighting re-design of the Deery Honda showroom wasn’t motivated by cost savings. The main goal was to increase the visibility of the showroom while improving the atmosphere for their customers. A significant amount of electricity costs were saved with the use of LED lighting technology in the design.

The priority of the lighting re-design of the Deery Honda showroom wasn’t motivated by cost savings. The main goal was to increase the visibility of the showroom while improving the atmosphere for their customers. A significant amount of electricity costs were saved with the use of LED lighting technology in the design.

Prior to the upgrade, the showroom did not meet Brad Deery standards; the showroom was not attracting their customer’s attention.

The project was divided into several phases. The first phase was the showroom and other interior lighting. The next phase was to increase the visibility of the main facade of the building.

The main facade phase wasn’t as simple as putting floods on poles. It required our engineering team to consider Amperage, beam spreads, total lumens, custom pole brackets, EPA wind loads, and several site visits. The design used four different beam spreads and three different wattage LED fixtures.

Huffman’s Farm and Home Store

Fort Madison, Iowa

Annual Cost Savings: $5,800

Square Footage: 22,000 ft2

Annual kWH Savings: 51,000 kWH

Annual kW Savings: 12 kW

Project Summary:

Retailers like Huffman’s are always on the lookout for cost-saving ideas. Huffman’s had been searching for the right lighting efficiency project for years. It wasn’t until they met Energyficient and our engineered approach that they were able to approve a project. Their project started like many others with one primary goal in mind: cost savings. Huffman’s operates their stores seven days a week for total annual hours of operation at 4500. Their retail business wouldn’t tolerate lower lighting levels with an existing lighting system that was made up of full wattage 32W T8, and 2-lamp 8-ft slim-line 65W lamps in standard strip fixtures that were lamped with 700 series, cool white (4100K) T8 and T12 lamps. We engineered a new reflector retrofit kit that improved both the horizontal foot candles and the vertical foot candles on the store shelves. This new kit used our high-lumen 5000K 32W T8 4-ft lamp. These new high-lumen lamps, when combined with high-efficiency ballast, create a super system that produces more than 98 lumens per watt. They also needed an answer to the fading in their clothing section that was caused by fluorescent lamps. Energyficient found a method of removing 99.9% of the harmful UV-rays from the fluorescent tubes.

Human Return on Investment:

Customers comment on how clean and tidy the store looks. Curb appeal is one thing, but maintaining a good retail image once a customer enters the store was very important to Huffman’s.

Project Benefits:

- Improved visual acuity (brighter, whiter lights)

- Elimination of UV fading of clothes

- Electricity and maintenance cost savings

Project Information

| Square Footage | 22,000 ft2 |

| Return on Investment | 36% |

| Payback | 33 months |

| Electric Cost Savings (Annually) | $5,800 |

| Incentives Achieved | Alliant Rebate $8000 |

| Total Watts Saved | 11,240 Watts |

| kWH Annual Savings | 50,580 kWH |

| kW’s Removed | 11.24 kW |

| Lamp Types Removed from Inventory | 2 |

| Affected Fixtures | 286 |

| Occupancy Sensors | 0 |

| New Fixtures Installed | 2 |

| Ballasts Installed | 284 |

| Reflector Kits Installed | 273 |

| CFL’s Installed | 0 |

| T8 Lamps Installed | 900 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 116,334.00 lbs |

| Nitrogen Oxide (NOx) | 238.43 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 407.62 lbs |

| Mercury (Hg) | 1,380.83 lbs |

| Carbon Monoxide (CO) | 18.77 lbs |

Natural Resources Savings

| Coal | 24,784 lbs |

| Oil | 150.22 gal |

| Natural Gas | 839 gal |

Delavan-Darien School District

Delavan, WI

Annual Cost Savings: 12,074.39

Annual kWH Savings: 111,119 kWH

Annual kW Savings: 28.49 kW

Project Summary:

This exterior lighting upgrade of Delavan-Darian School District in Wisconsin included a complete fixture and pole replacement of the sombrero top fixtures at the admin building, complete fixture replacement of the sombrero top fixtures at the high school. As well as new LED canopy fixtures in place of existing recessed can lights at the high school, Phoenix Middle School, and Turtle Creek. Occupancy based controls on all LED shoebox and cobra head fixtures in parking lots. New architectural LED uplight for the canopy at the high school. As well as additional LED shoebox fixtures on existing poles in the faculty lot at Turtle Creek for future parking lot expansion.

This exterior lighting upgrade of Delavan-Darian School District in Wisconsin included a complete fixture and pole replacement of the sombrero top fixtures at the admin building, complete fixture replacement of the sombrero top fixtures at the high school. As well as new LED canopy fixtures in place of existing recessed can lights at the high school, Phoenix Middle School, and Turtle Creek. Occupancy based controls on all LED shoebox and cobra head fixtures in parking lots. New architectural LED uplight for the canopy at the high school. As well as additional LED shoebox fixtures on existing poles in the faculty lot at Turtle Creek for future parking lot expansion.

Human Return on Investment:

Project Benefits:

- Energy cost savings

- Improved environmental safety for students and faculty

- Elimination of dark spots, creating continuity

- Brighter outdoor lighting

Project Information

| Return on Investment | 12% |

| Payback | 86.7 months |

| Electric Cost Savings (Annually) | $10,078.98 |

| Maintenance Savings (Annually) | $1,995.41 |

| Incentives Available | $6,180 |

| Total Watts Saved | 28,490 |

| kWh Annual Savings | 111,989 |

| kW's Removed | 28.49 |

| Lamp Types Removed from Inventory | 4 |

| Affected Fixtures | 222 |

| New Fixtures Installed | 211 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 258,917.72 lbs |

| Nitrogen Oxide (NOx) | 546.39 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 973.29 lbs |

| Mercury (Hg) | 2,575.74 mg |

| Carbon Monoxide (CO) | 106.50 lbs |

Natural Resources Savings

| Coal | 54,874.43 lbs |

| Oil | 332.61 gal |

| Natural Gas | 1,858.64 gal |

Mt. Vernon Schools

Mt. Vernon, Missouri

Annual Cost Savings: $52,387

Square Footage: 245,884 ft2

Annual kWH Savings: 744,148 kWH

Annual kW Savings: 312 kW

Project Summary:

Mt. Vernon R-5 School District is a Class AAA school system consisting of 4 schools, with 2 state colleges and several private colleges within 40 miles. They serve approximately 1500 K-12 students. The Mt. Vernon R-5 school district is committed to helping students reach their full potential and to help instill a love of learning.

Mt. Vernon R-5 School District is a Class AAA school system consisting of 4 schools, with 2 state colleges and several private colleges within 40 miles. They serve approximately 1500 K-12 students. The Mt. Vernon R-5 school district is committed to helping students reach their full potential and to help instill a love of learning.

The top priorities for this project were energy savings, updated lighting in older classrooms, user comfort and maintenance savings. Energyficient’s team of professionals worked with the school district to evaluate four district schools and create a comprehensive design plan that would best fit their needs.

Three of the four schools were found to be good candidates for lighting upgrades. The intermediate school was found to be up-to-date and there was no financial incentive to update the buildings’ lighting system.

While the Elementary School did have a somewhat recent addition, there were enough areas presenting old technology for it to be included in the project. The building had a mix of T8 and T12 systems, both of which were updated.

The Mt. Vernon Junior High School presented many opportunities for savings by using an engineered design approach. The main building gymnasium was recessed 2’x2′ metal halide fixtures and the hallway around the gym contained fixtures with missing or broken lenses and were well beyond their usable life.

The Mt. Vernon High School building presented almost all old technology with just a few existing T8 fixtures, mostly in the new addition. The gymnasium had recently been updated to T5 fixtures, but the weight room on the gym mezzanine had 2’x2′ metal halide fixtures in a recessed ceiling.

The number of different types of light bulbs and ballasts it required to maintain the old system was a drain on resources, both financially and physically. There were 4 generations of lighting technology in place at the schools.

All outdoor fixtures were replaced with LED fixtures, providing a super long life of 20+ years. Lighting controls were applied wherever fiscally responsible, and reflectors and socket kits were used to reduce lamp count and lamp type in many existing fixtures.

All outdoor fixtures were replaced with LED fixtures, providing a super long life of 20+ years. Lighting controls were applied wherever fiscally responsible, and reflectors and socket kits were used to reduce lamp count and lamp type in many existing fixtures.

All gymnasiums will be provided with bi-level lighting control through a “real key” switch. Gymnasiums are a multipurpose room as much as they are gyms anymore. It’s not required and wasteful to light the gym for competitive sports levels when its being used for recreational events or normal physical education activities. The new systems will have a low mode with the light level tuned to the stadards for general purpose activities and the high levels tuned to highest sport activity standard. (See inset)

Lighting controls will also be provided in all rooms that presented a financial case to support them. See space listing for exact locations and details. Controls will be passive infrared for all areas with the addtion of microphonic control for classrooms. These systems and our attention to the design will ensure a smooth operating system.

The media center rooms and computer labs (as described in our space listing) in all the buildings will recieve the latest generation, Volumetric, LED recessed lumenaires to provide a bi-level lighting system that will be beneficial to the learning environment. These new fixtures will be able to be used in a low mode for many day to day activities and in a high mode for special events or special activities. Media centers for example may choose to run the lights in low mode until there is a specific group in the room.

Most all screw in lamps will be eliminated from the system. This improves sustainability and consolidates lamp types.

The south building at the middle school will get all new recessed fixtures in a new layout to provide uniform light levels and eliminate the need to find custom lenses for the existing fixtures.

All existing T8 systems found within the buildings other than the Intermediate School will be updated to the latest T8 technology ballasts and lamps. Replacing existing T8 lamps makes financial sense by providing a payback and also updates all lamp types to lamps that are compliant with the latest in Federal Government regulations. Replacing all lamps also provides a unique opportunity to schedule future group relampings thereby providing additional maintenance and cost savings and eliminates warranty confusion.

Project Information

| Square Footage | 245,884 ft2 |

| Return on Investment | 15% |

| Payback | 80 months |

| Electric Cost Savings (Annually) | $52,387 |

| Incentives Achieved | $5,420 |

| Total Watts Saved | 286.925 Watts |

| kWH Annual Savings | 744,148 kWH |

| Affected Fixtures | 3,408 |

| Occupancy Sensors | 306 |

| New Fixtures Installed | 1,990 |

| Ballasts Installed | 1,529 |

| LED Fixtures Installed | 39 |

| T8 Lamps Installed | 16 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 1,649,794.88 lbs |

| Nitrogen Oxide (NOx) | 3,596.15 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 5,129.34 lbs |

| Mercury (Hg) | 14,036.21 mg |

| Carbon Monoxide (CO) | 216.66 lbs |

Natural Resources Savings

| Coal | 352,000 lbs |

| Oil | 1,638 gal |

| Natural Gas | 9,114 gal |

Wellsville – Middletown Schools

Wellsville, Missouri

Annual Cost Savings: $18,883.76

Square Footage: 60,000 ft2

Annual kWH Savings: 268,235 kWH

Annual kW Savings: 78 kW

Project Summary:

![]()

Wellsville-Middletown R-1 School District serves approximately 150 square miles near the center of Missouri. The total district population in 2010 was 2,629. The schools serve a total of 466 children in grades PK-12, with an average of 11 students per full-time instructor.

Priorities for this project were two-fold. The school district was interested in sustainable energy and maintenance savings, as well as user comfort and satisfaction. Energyficient’s team of professionals worked with the school district to design a comprehensive design plan that would meet all of the project goals.

One way to save both time and money is to consolidate lamp types. Priority was given to consolidation, creating uniformity across the school district. Nearly all of the existing T8 lamps in all of the buildings were replaced with 4ft, 28W High Vision, 5000K energy saving T8 lamps. All of the existing 8ft lamps were also replaced with 4ft lamps, reducing inventory costs and improving safety by eliminating cumbersome and expensive 8ft lamps.

Lighting controls, including infrared, ultrasonic, and microphonic occupancy controls and digital time switches were applied wherever fiscally responsible. Reflectors and socket kits were also used to reduce lamp count and lamp type in many of the existing fixtures. In addition, all of the outside light fixtures were replaced with LED fixtures, providing a long-term, sustainable, secure night time environment.

Human Return on Investment:

The improved lighting in these schools is a benefit to both the students and the instructors. Better lighting provides improved visual clarity, reduces eye strain and improves productivity. Higher quality lighting also provides for a more comfortable working environment.

The improved lighting in these schools is a benefit to both the students and the instructors. Better lighting provides improved visual clarity, reduces eye strain and improves productivity. Higher quality lighting also provides for a more comfortable working environment.

Project Benefits:

- Energy Savings

- Maintenance and Repairs Savings

- Improved safety from brighter light levels

- Productivity increases from improved light levels

- Fewer errors because of lighting quality

- More comfortable place to work

Project Information

| Square Footage | 60,000 ft2 |

| Return on Investment | 13% |

| Payback | 89.86 months |

| Electric Cost Savings (Annually) | $18,883.76 |

| Incentives Achieved | $2,700 |

| Total Watts Saved | 68,472 Watts |

| kWH Annual Savings | 268,235 kWH |

| kW's Removed | |

| Lamp Types Removed from Inventory | 11 |

| Affected Fixtures | 1035 |

| Occupancy Sensors | 147 |

| New Fixtures Installed | 179 |

| Ballasts Installed | 798 |

| LED fixtures installed | 97 |

| T5 lamps installed | 164 |

| T8 Lamps Installed | 2034 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 605,676.97 lbs |

| Nitrogen Oxide (NOx) | 1,320.23 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 1,883.10 lbs |

| Mercury (Hg) | 5,153.01 mg |

| Carbon Monoxide (CO) | 79.54 lbs |

Natural Resources Savings

| Coal | 129,485.91 lbs |

| Oil | 784.84 gal |

| Natural Gas | 4,385.80 gal |

Champaign School District #4

Champaign, IL

Annual Cost Savings: $83,482.99

Annual kWH Savings: 1,003,401 kWH

Annual kW Savings: 343.49 kW

Project Summary:

Champaign Community Unit School District #4 is a large school district with 18 campuses. This district serves over 9,600 students in grades pre-K through 12, and they employ over 1,400 educators. Energyficient has done work at 4 of the 18 schools in this district, including all 3 of the junior high schools as well as the new Central High School facility.

As with any school, efficiency is key. Because of their strict budgets, it is in the best interest of the school district to save money wherever they can. The goals of this project were to reduce energy costs, improve the quality of light, and consolidate the types of lamps used, providing uniformity across the district.

Occupancy sensors were added to the gymnasium, reducing electric usage by turning the lights off whenever the area is not being used. In addition, high intensity fluorescent fixtures with hinged wire guards were installed in the gymnasium, providing the most durable lighting available on the market today.

Human Return on Investment:

The improved lighting in these schools is a benefit to both the students and the instructors. Better lighting provides improved visual clarity, reduces eye strain and improves productivity. Higher quality lighting also provides for a more comfortable working environment.

Project Benefits:

- Energy Savings

- Maintenance and Repairs Savings

- Improved safety from brighter light levels

- Productivity increases from improved light levels

- Fewer errors because of lighting quality

- More comfortable place to work

- Less taxing on air conditioning systems

- Removing over 8,000 watts of lighting heat

Project Information

| Square Footage | XX ft2 |

| Return on Investment | 13.97% |

| Payback | 85.88 months |

| Electric Cost Savings (Annually) | $83,482.99 |

| Incentives Achieved | $183,517.39 |

| Total Watts Saved | 343,493 Watts |

| kWH Annual Savings | 1,003,401 kWH |

| kW's Removed | 343,490 |

| Lamp Types Removed from Inventory | 7 |

| Affected Fixtures | 1,956 |

| Occupancy Sensors | 12 |

| New Fixtures Installed | 331 |

| Ballasts Installed | 3,789 |

| Reflector Kits Installed | 1,661 |

| CFL's Installed | 194 |

| T8 Lamps Installed | 9,037 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 2,271,700.57 lbs |

| Nitrogen Oxide (NOx) | 5,539.78 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 10,124.32 lbs |

| Mercury (Hg) | 35,821.43 mg |

| Carbon Monoxide (CO) | 330.12 lbs |

Natural Resources Savings

| Coal | 491,666.64 lbs |

| Oil | 2,980.10 gal |

| Natural Gas | 16,653.17 gal |

North Harrison R-III School District

Eagleville, Missouri

Annual Cost Savings: $14,000

Square Footage: 50,854 ft2

Annual kWH Savings: 128,170 kWH

Annual kW Savings: 42 kW

Project Summary:

This project started with one goal in mind: energy savings. During our pre-project interview process the project engineers at Energyficient discovered the school wanted to increase the light output in its gymnasium, consolidate lamp and ballast types, and replace many fixtures that were either not safe or un-repairable. The project included 102 new interior light fixtures and 15 new outdoor fixtures. In an effort to provide sustainable energy savings through system maintenance cycles, Energyficient retrofitted 250 recessed fixtures using specially engineered reflector kits that reduce the lamp count in a four-lamp fixture to two, and utilize easily replaced ballasts and sockets. These kits are highly recommended because they increase the efficiency or performance of the old fixture by 50 percent or more. Energyficient upgrades the lamp color to a more neutral 5000K high vision color that dramatically increases the impact of the upgrade. We also consolidated their existing light bulb inventory from over 11 different lamp types down to just three. Imagine the savings in maintenance time and materials!

Human Return on Investment:

The gym was especially challenging because of the type of acoustic ceiling material. We wanted recessed fixtures but needed to increase the size from 2’x2’ to 2’x4’ to accommodate the new 6-lamp T8 light fixtures. Working closely with our carpentry contractor and our electrical contractor, Energyficient made the impossible happen. The gym is now brighter than ever before and we were able to maintain a very clean flush look with the new fixtures. The high school locker rooms also needed a safety upgrade to watertight fixtures with unbreakable lenses. Instead of taking a one-for-one approach, we redesigned these areas to provide the perfect amount of light with the fewest possible fixtures, thus enabling the safety upgrade to be easily included in the project.

Project Benefits:

- Improved visual acuity (brighter, whiter lights)

- Brighter gymnasium, meets IES requirements for high school tournament play

- Replaced worn-out light fixtures

- Upgraded safety in the locker rooms

- Electricity and maintenance cost savings

Project Information

| Square Footage | 50,854 ft2 |

| Return on Investment | 31% |

| Payback | 36 months |

| Electric Cost Savings (Annually) | $11,500 |

| Incentives Achieved | KCPL Rebate $12,000 |

| Total Watts Saved | 42,000 Watts |

| kWH Annual Savings | 128,170 kWH |

| kW’s Removed | 42 kW |

| Lamp Types Removed from Inventory | 8 |

| Affected Fixtures | 560 |

| Occupancy Sensors | 0 |

| New Fixtures Installed | 102 |

| Ballasts Installed | 386 |

| Reflector Kits Installed | 283 |

| CFL’s Installed | 12 |

| T8 Lamps Installed | 1,200 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 293,764.86 lbs |

| Nitrogen Oxide (NOx) | 640.34 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 913.34 lbs |

| Mercury (Hg) | 2,499.31 lbs |

| Carbon Monoxide (CO) | 38.58 lbs |

Natural Resources Savings

| Coal | 62,803 lbs |

| Oil | 380.66 gal |

| Natural Gas | 2,127 gal |

United States Gypsum Co

Sperry, Iowa

Annual Cost Savings: $210,959.08

Square Footage: 290,000 ft2

Annual kWH Savings: 2,604,433 kWH

Annual kW Savings: 332 kW

Project Summary:

USG is a leading manufacturer of building products and innovative solutions. USG has led the manufacturing industry with innovations and products that set new standards for design, productivity, and performance for customers all over the world. After a comprehensive audit of their southeast Iowa facility, our team discovered many deficiencies in the light quality, fixture quantity, and system wiring. With much of the existing system over 50 years old, it was becoming increasingly expensive to operate and maintain the inefficient and obsolete technology.

USG is a leading manufacturer of building products and innovative solutions. USG has led the manufacturing industry with innovations and products that set new standards for design, productivity, and performance for customers all over the world. After a comprehensive audit of their southeast Iowa facility, our team discovered many deficiencies in the light quality, fixture quantity, and system wiring. With much of the existing system over 50 years old, it was becoming increasingly expensive to operate and maintain the inefficient and obsolete technology.

After meeting with key decision makers, our design team engineered an effective LED lighting solution that met all the priorities and goals USG needed for safe, efficient, and profitable production. To reduce maintenance and associated costs, long life LED products were installed in offices, production areas, and high abuse areas where Class 2 Division 2 classified fixtures were required. Other fixtures were retrofitted to keep overall project cost down, while still providing the benefits of new fixtures. To provide a more comfortable work environment, overall color temperature was specified at 5,000K, which is a neutral white color similar to daylight on a clear day. A human centric lighting system benefits all working shifts, giving them consistent lighting with improved visual clarity.

After meeting with key decision makers, our design team engineered an effective LED lighting solution that met all the priorities and goals USG needed for safe, efficient, and profitable production. To reduce maintenance and associated costs, long life LED products were installed in offices, production areas, and high abuse areas where Class 2 Division 2 classified fixtures were required. Other fixtures were retrofitted to keep overall project cost down, while still providing the benefits of new fixtures. To provide a more comfortable work environment, overall color temperature was specified at 5,000K, which is a neutral white color similar to daylight on a clear day. A human centric lighting system benefits all working shifts, giving them consistent lighting with improved visual clarity.

To optimize energy savings and further extend fixture life, occupancy sensors were installed in storage rooms, warehouses, offices, restrooms and other areas where they were found to be safe and fiscally responsible to the projects financial case. Automatically turning lights on/off is an easy, worry free method of reducing power consumption – saving you money on your electric bill!

To complete the comprehensive upgrade, outdoor fixtures were replaced with new LED fixtures. Upgrading from the HID fixtures made a big difference not only in annual savings but also nighttime visibility. LED fixtures outperform traditional fixtures, helping eliminate dark spots and shadows that are common with HID technology. And with higher CRI, LED fixtures illuminate areas more clearly with bright, white light.

To complete the comprehensive upgrade, outdoor fixtures were replaced with new LED fixtures. Upgrading from the HID fixtures made a big difference not only in annual savings but also nighttime visibility. LED fixtures outperform traditional fixtures, helping eliminate dark spots and shadows that are common with HID technology. And with higher CRI, LED fixtures illuminate areas more clearly with bright, white light.

After our comprehensive lighting upgrade, USG now benefits from fixed overhead cost savings. LED solutions has lowered their monthly electric bill, reduced maintenance costs, and consolidated their lighting inventory. Creating sustainable, lifelong savings while improving safety and comfort is something USG will benefit from year after year.

Project Benefits:

- Bright, crisp light with balanced uniformity for a safer, comfortable work environment

- Sustainable annual savings & fixed overhead costs

- Durable, hazardous location safe fixtures for long term reliability and performance

- Instant on - no warm up/turn on time

- Reduced inventory by consolidated fixture and lamp types

- Complete & comprehensive upgrade - inside and out

Project Information

| Square Footage | 290,000 ft2 |

| Return on Investment | 28% |

| Payback | < 5 years |

| Electric Cost Savings (Annually) | $210,959.08 |

| Incentives Achieved | Alliant Energy Rebate ≈$200k |

| Total Watts Saved | 325,588 Watts |

| kWH Annual Savings | 2,604,433 kWH |

| kW Annual Savings | 332 |

| Lamp Types Removed from Inventory | 22 |

| Affected Fixtures | 2,527 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 5,990,196.00 lbs |

| Nitrogen Oxide (NOx) | 12,277.30 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 20,989.13 lbs |

| Mercury (Hg) | 71,101.02 lbs |

| Carbon Monoxide (CO) | 966.24 lbs |

Natural Resources Savings

| Coal | 1,276,172.19 lbs |

| Oil | 7,735.17 gal |

| Natural Gas | 43,225.06 gal |

Wells Distribution Center

Centerville, Iowa

Annual Cost Savings: $47,197.01

Square Footage: 187,000 ft2

Annual kWH Savings: 641,246 kWH

Annual kW Savings: 116 kW

Project Summary:

![]() Wells Vehicle Electronics is a premier global manufacturer of vehicle electronics. They are a respected brand that manufactures tens of thousands of components for a large network of distributors and retail businesses. Wells was founded at the dawn of the automotive industry.

Wells Vehicle Electronics is a premier global manufacturer of vehicle electronics. They are a respected brand that manufactures tens of thousands of components for a large network of distributors and retail businesses. Wells was founded at the dawn of the automotive industry.

When it was time to update the lighting system in their state-of-the-art distribution center, the Wells team turned to the professionals at Energyficient. The project featured scotopically enhance T8 lamps, occupancy sensors, induction and LED outdoor area lights, and reflector kits for troffers and strip fixtures to allow for a reduction in overall lamp count and a consolidation of lamp types.

Project Benefits:

- Lower Electric Bill

- Maintenance Materials and Labor Savings

- Brighter Work Environment

- Brighter Outdoor Lighting

- Improved Visual Clarity

Project Information

| Square Footage | 187,000 ft2 |

| Return on Investment | 67% |

| Payback | 17.99 months |

| Electric Cost Savings (Annually) | $47,197.01 |

| Incentives Achieved | $60,400 |

| Total Watts Saved | 96,527 Watts |

| kWH Annual Savings | 641,246 kWH |

| kW's Removed | 116,000 |

| Lamp Types Removed from Inventory | 2 |

| Affected Fixtures | 622 |

| Occupancy Sensors | 438 |

| New Fixtures Installed | 425 |

| Ballasts Installed | 183 |

| Reflector Kits Installed | 142 |

| CFL's Installed | 0 |

| T8 Lamps Installed | 365 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 1,474,906.54 lbs |

| Nitrogen Oxide (NOx) | 3,022.92 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 5,167.94 lbs |

| Mercury (Hg) | 17,506.5 mg |

| Carbon Monoxide (CO) | 237.91 lbs |

Natural Resources Savings

| Coal | 314,000 lbs |

| Oil | 1,470 gal |

| Natural Gas | 8,148 gal |

Brown Bear Corp.

Corning, Iowa

Annual Cost Savings: $9,500.82

Square Footage: 35,000 ft2

Annual kWH Savings: 75,343 kWH

Annual kW Savings: 40.25 kW

Project Summary:

Brown Bear Corporation is a heavy equipment manufacturer specializing in building products for the environmental, pipeline, and utility industries. Brown Bear was founded in 1961 by Roscoe Brown. They began manufacturing a line of products for pipeline and drain tile backfilling in 1968, and their first tractor line of machines was built in 1976. All of the company business, including engineering, design, fabrication, paint and assembly, as well as sales and support, is handled out of their 40,000 square foot facility in Corning, Iowa.

The lighting system in Brown Bear’s facility was showing signs of age. Light levels had dropped considerably from when it was new, leading to less than ideal conditions for their production work. The old metal halide and T12 Fluorescent lighting system was also very inefficient, leading to high maintenance and electricity costs. As company president, Mr. Brown was searching for a way to reduce his monthly expenses while improving the overall quality of the lighting in his facility without spending more than he needed to.

Energyficient’s team of professionals met with Mr. Brown and through our consulting/interview process helped him understand what was possible with a lighting efficiency project. Together, we determined the priorities for his project design and began our work. With the help of South West Iowa REC efficiency program rebate, the project payback was shorter than his expectations making the approval of the project a no-brainer.

Human Return on Investment:

Better lighting leads to more productive workers. While the main goal of this project was the long-term efficiency and cost savings, the improved lighting was a welcome addition. Employees immediately noticed the difference, both in the production areas as well as in the office.

Better lighting leads to more productive workers. While the main goal of this project was the long-term efficiency and cost savings, the improved lighting was a welcome addition. Employees immediately noticed the difference, both in the production areas as well as in the office.

Project Benefits:

- Lower Electric Bill

- Maintenance Materials and Labor Savings

- Brighter Work Environment

- Brighter Outdoor Lighting

- Improved Visual Clarity

Project Information

| Square Footage | 35,000 ft2 |

| Return on Investment | 59% |

| Payback | 20.51 months |

| Electric Cost Savings (Annually) | $9,500.82 |

| Incentives Achieved | |

| Total Watts Saved | 39,863 Watts |

| kWH Annual Savings | 75,343 kWH |

| Lamp Types Removed from Inventory | 1 |

| Affected Fixtures | 235 |

| Reflector Kits Installed | 72 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 173,289.16 lbs |

| Nitrogen Oxide (NOx) | 355.17 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 607.19 lbs |

| Mercury (Hg) | 2056.87 mg |

| Carbon Monoxide (CO) | 27.95 lbs |

Natural Resources Savings

| Coal | 36,918.13 lbs |

| Oil | 223.77 gal |

| Natural Gas | 1,250.45 gal |

John Deere Horicon 101 Works

Horicon, WI

Annual Cost Savings: >$125,000

Square Footage: > 225,000 ft2

Annual kWH Savings: > 1,250,000 kWH

Annual kW Savings: >120 kW

Project Summary:

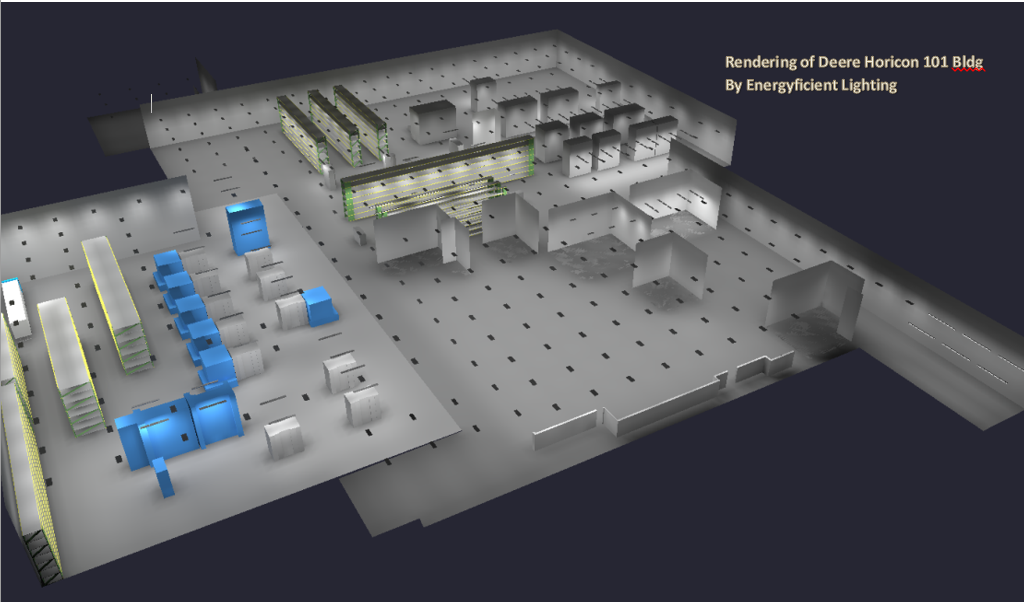

John Deere’s Horicon 101 Works is a 225,000 square foot, world class metal stamping facility that processes over 50,000 tons of steel a year. This is a formidable facility with some of the largest metal presses on the planet! A progressive manufacturing facility goes through a lot of changes in process improvements and new equipment over its life. This facility is over 25 years old and so was the lighting system.

It was time for a new lighting system. Complaints from the employees were at an all-time high. Light levels were diminished by age, and dirt. The existing fixture spacing was not designed for the precision required of today’s production standards making shadows and uniformity a real problem. Existing lighting circuits were not lined up with the processes of today requiring lights to be on in unpopulated areas and during off shifts.

Facility engineers contacted Energyficient and several other potential providers to develop the best and most versatile new lighting system for them – with a catch. It needed to solve all their lighting problems, AND pay for itself through electricity cost savings in a time frame found acceptable by the stakeholders responsible for the bottom line at the facility.

Energyficient invested the time and effort into redesigning the entire lighting system. Our engineered approach to lighting efficiency separates us from our competitors.

We rendered the entire facility for them. The rendering provides amazing accuracy and details that take all the guess work out of a new design.

Human Return on Investment:

Better lighting doesn't always mean brighter. Cost of production includes the time it takes employees to perform their given tasks or jobs. The increased foot candles and improved uniformity greatly improved employees visual acuity.

Project Benefits:

Outdoor lighting was included in the project. All outdoor lighting was replaced by new LED fixtures that were specifically engineered for each area. Parking lots, driveways, the sign, and  entrances were all brightened up and overall visibility improved by reducing the glare of the old fixtures. We were able to increase the amount of light outdoors, reduce the electricity used by over 50% and meet dark sky requirements, making the facility a little more friendly to the night sky.

entrances were all brightened up and overall visibility improved by reducing the glare of the old fixtures. We were able to increase the amount of light outdoors, reduce the electricity used by over 50% and meet dark sky requirements, making the facility a little more friendly to the night sky.

Visibility was dramatically improved. The large presses were fitted with new task level light fixture arrays that got the light inside the presses  improving safety and quality control.

improving safety and quality control.

Glare from harsh HID fixtures was eliminated, reducing eyestrain and making it easier to spend time in the plant.

Our engineered approach to the design allows the entire system is modular and can be moved and adjusted as processes change in the future.

Dark walls in the office space were brightened up and the overall space was transformed. We removed the old parabolic (full cutoff) and replaced them with new volumetric style linear fluorescent and LED recessed fixtures.

Project Information

| Square Footage | >225,000 ft2 |

| Return on Investment | <25% |

| Payback | <72 months |

| Electric Cost Savings (Annually) | >$125,000 |

| Incentives Achieved | Focus On Energy >$40,000 |

| Total Watts Saved | >120,000 Watts |

| kWH Annual Savings | >1,250,000 kWH |

| kW's Removed | >120 kW |

| Lamp Types Removed from Inventory | >10 |

| Affected Fixtures | >2000 |

| Occupancy Sensors | 493 |

| New Fixtures Installed | >1000 |

| Ballasts Installed | 355 |

| LED Fixtures Installed | 207 |

| T5 Lamps Installed | 3500 |

| T8 Lamps Installed | 1100 |

Pollution Reduction

| Global Warming (Carbon Dioxide, CO2) | 2,846,354.01 lbs |

| Nitrogen Oxide (NOx) | 6,006.64 lbs |

| Acid Rain (Sulfur Dioxide, SO2) | 10,699.68 lbs |

| Mercury (Hg) | 28,315.81 lbs |

| Carbon Monoxide (CO) | 1,170 lbs |

Natural Resources Savings

| Coal | 603,249 lbs |

| Oil | 3,656 gal |

| Natural Gas | 20,432 gal |

Project Summary:

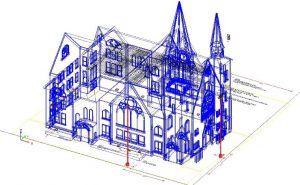

Steeple Lighting

In 2009, local philanthropist Gretchen Miller contacted lighting designer and CEO of Energyficient Systems, Chad Palmer, about illuminating the steeple of St. John Catholic Church.  As the project developed, people began wondering about lighting up other historic downtown landmarks, which have been an integral feature of Burlington’s skyline as they are the first sight visitors see crossing the river. After years of fundraising and preparation, the Burlington Lightscape Committee unveiled their most ambitious project to date – illuminating eight of Burlington’s most well-known landmarks. Each day as dusk falls, the downtown skyline is transformed and brought to life by the soft glow of LED lights, accentuating the remarkable architecture of century old buildings.

As the project developed, people began wondering about lighting up other historic downtown landmarks, which have been an integral feature of Burlington’s skyline as they are the first sight visitors see crossing the river. After years of fundraising and preparation, the Burlington Lightscape Committee unveiled their most ambitious project to date – illuminating eight of Burlington’s most well-known landmarks. Each day as dusk falls, the downtown skyline is transformed and brought to life by the soft glow of LED lights, accentuating the remarkable architecture of century old buildings.

Fueled by accomplished engineers and designers passionate about the lighting industry, Energyficient Systems worked to provide exemplary design, leadership, and construction services – helping make the Lightscape vision a reality. Phase one of the construction project involved illuminating six individual downtown churches, with the unique feature of having them all controlled from a single point. Each steeple became a focal point in the design, with the facade lighting tied to it. Depending on the location, LED lighting would cover one to three sides of the building. Using AGi32, a professional lighting design software, our design engineering team created accurate 3D models of each church to show committee members and supporters what the final project would look like and aid in the design process.

Fueled by accomplished engineers and designers passionate about the lighting industry, Energyficient Systems worked to provide exemplary design, leadership, and construction services – helping make the Lightscape vision a reality. Phase one of the construction project involved illuminating six individual downtown churches, with the unique feature of having them all controlled from a single point. Each steeple became a focal point in the design, with the facade lighting tied to it. Depending on the location, LED lighting would cover one to three sides of the building. Using AGi32, a professional lighting design software, our design engineering team created accurate 3D models of each church to show committee members and supporters what the final project would look like and aid in the design process.

Each site presented its own unique challenges that had to be overcome in the design. Light trespass was the major issue. Light pollution can be as big of a concern in a small town as it is in a big city. Trees, surrounding buildings, and other constraints also had to be considered. And with the project being funded publicly through donations, it was critical that the lighting and control system be affordable. Energyficient chose to use Beacon’s Alpha series luminaires for its versatility, functionality, and compatibility. Throughout the project, 25 different fixture models were used to meet the diverse lumen and distribution needs. To take control of the outdoor lighting, Hubbell’s wireless wiSCAPE management platform was used. Installing internal and external fixture modules gave churches individual local control of their exterior lighting, which was tied back to City Hall through a wireless gateway network. Having central control allows the system to be managed, monitored, and measured quickly and efficiently.

Lighting the skyline of historic downtown Burlington proved that outdoor lighting and controls offered tremendous value not only in architectural design, but also in increased savings. Coupling  the new LED luminaries together with advanced controls meant churches would be seeing a decrease in power consumption – ultimately saving them money on their electric bill each month. Utilizing state-of-the-art technology ensures system integrity throughout it’s lifespan. Planning for the future, normal use light output was dimmed 20% to further extend the systems’s life – something that would have been much more challenging with traditional lighting and controls.

the new LED luminaries together with advanced controls meant churches would be seeing a decrease in power consumption – ultimately saving them money on their electric bill each month. Utilizing state-of-the-art technology ensures system integrity throughout it’s lifespan. Planning for the future, normal use light output was dimmed 20% to further extend the systems’s life – something that would have been much more challenging with traditional lighting and controls.

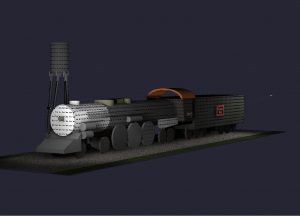

Burlington’s Locomotive

The railroad has played an important role in the history of Burlington. From the first rail line being incorporated in 1852 to George Westinghouse perfecting the air brake, the railroad and Burlington have a long history together. The Chicago, Burlington, and Quincy (CB&Q) steam locomotive has been on display at the downtown depot since 1961, when the railroad donated the locomotive to the city.

As one of Burlington’s prominent attractions, re-illuminating the locomotive was a must. Energyficient’s design team engineered an LED solution that dramatically transformed the nighttime display. Working together with local contractors, new poles were strategically installed around the locomotive to meet the needs of our engineered design. Modern LED fixtures were installed, casting bright, uniform light across the locomotive. Eliminating dark spots, while controlling light trespass and glare has made Burlington’s locomotive an outstanding point of interest for the community and it’s visitors.

As one of Burlington’s prominent attractions, re-illuminating the locomotive was a must. Energyficient’s design team engineered an LED solution that dramatically transformed the nighttime display. Working together with local contractors, new poles were strategically installed around the locomotive to meet the needs of our engineered design. Modern LED fixtures were installed, casting bright, uniform light across the locomotive. Eliminating dark spots, while controlling light trespass and glare has made Burlington’s locomotive an outstanding point of interest for the community and it’s visitors.

Project Information

| Total Light Fixtures | 103 |

| Total Watts | 9,848 |

| Total Lumens | 727,961 |

| Total Poles | 32 |